types of grinding Grinding machines can be used to create sharp cutting tools flat cylinder heads gear wheels cutting tools and much more This article explores 19 types of grinding machines and examines how they work how they differ and how much they might cost you 1 Angle Grinder

2022 11 28 Grinding in manufacturing is abrasive machining that is used to finish workpieces understanding what the grinding process is how it works as well as common types of grinding What is Grinding Process Grinding is a type of finishing process in mechanical processing with less machining and high precision What Are the Different Types of Grinding Machines There are many different types of grinding machines on the market each with its own unique applications Some common types of grinders include Bench Grinder A stationary grinding machine typically fixed on a workbench or table It features either one or two grinding wheels

types of grinding

types of grinding

https://cdn.thepipingmart.com/wp-content/uploads/2022/10/An-Introduction-to-the-Types-of-Grinding-Machines-1024x593.jpg

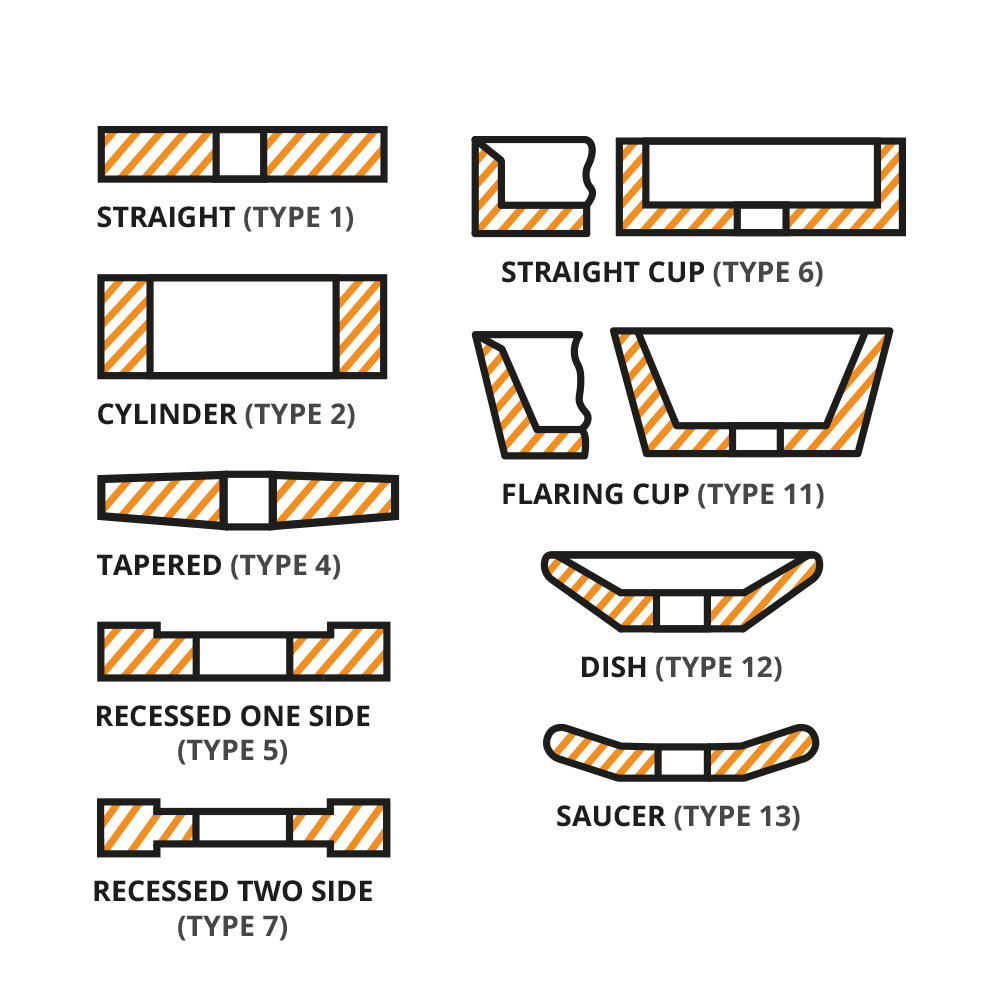

Classification Of Grinding Wheels Which Do I Need

https://www.highspeedtraining.co.uk/hub/wp-content/uploads/2016/09/grinding-wheels-colour.png

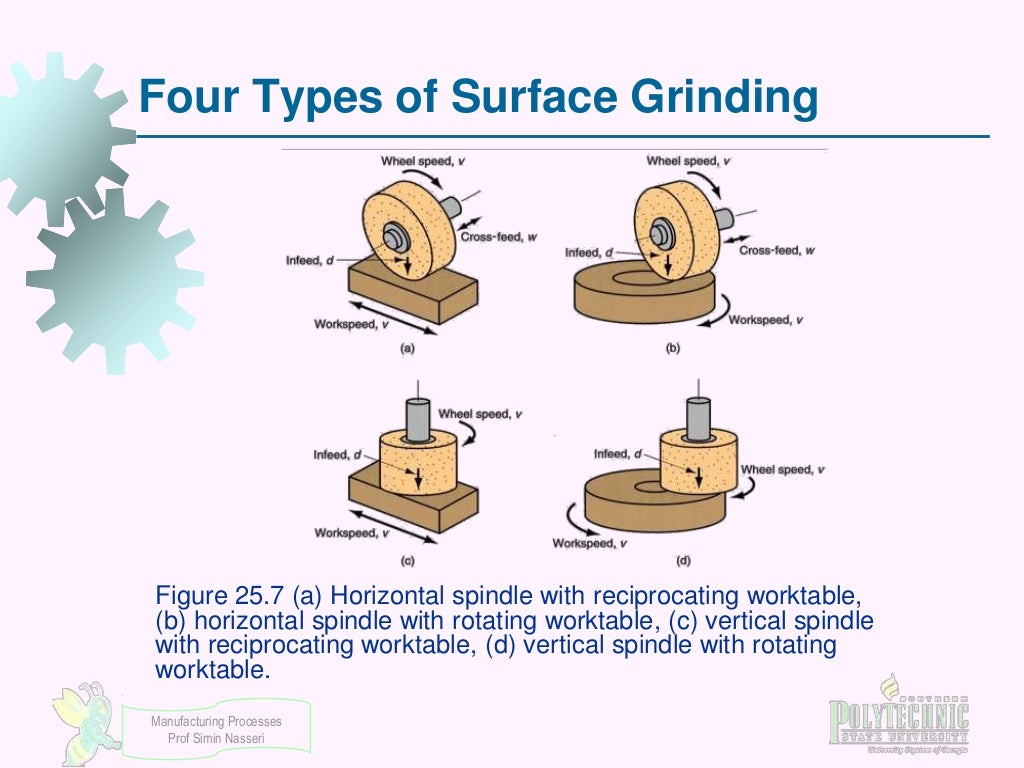

Chapter 25 grinding

https://image.slidesharecdn.com/chapter25grinding-131120192207-phpapp01/95/slide-12-1024.jpg

Grinding is an intricate abrasive machining process involving an abrasive wheel as a cutting tool It s renowned for its ability to produce very fine finishes and extremely accurate dimensions on metal parts Grinding involves a rotating grinding wheel made of abrasive particles which act as miniature cutting tools The following are the three types of centreless grinding Through feed Infeed End feed 1 Through Feed In this grinding the whole length of the bar or shaft is grinded which is placed on the work rest The amount of material removed is 0 02 to 0 3mm 2 Infeed This type of grinding is used to grind parts that require multiple profiles

Tailstock and headstock will hold the object and object will rotate between headstock and tailstock Hydraulic oil classification Hardness testing method Inside diameter grinding also called as internal grinding is used for grinding the inner diameter of tubular object Updated 5 1 2024 Published 7 3 2021 Machining 101 What is Grinding Grinding takes an abrasive often attached to a wheel and uses its many grains to cut a workpiece Variations on this process are useful for a wide variety of applications Machines Basics Grinding Evan Doran Associate Editor Modern Machine Shop

More picture related to types of grinding

Common Grinding Operations MechanicsTips

https://1.bp.blogspot.com/-rtg_RjLO7d0/WBNRPLtLNAI/AAAAAAAACYg/v_W1XtmT--M2e4jnB-FLmjvCggXtLwblACK4B/s1600/gallery_53_95_29302.jpg

14 TYPES OF GRINDING MACHINES Universal Grinding Corporation

https://universalgrinding.com/wp-content/uploads/2022/01/ug8.png

How To Choose From The Different Types Of Grinding Wheels Residence

https://www.residencestyle.com/wp-content/uploads/2019/12/Which-Grinding-Wheel-is-Right-for-Your-Application.jpg

Types of Grinding Operations There are numerous types of grinding operations which vary according to the shape of the wheel and the kinematic motions of the workpiece and wheelhead Some of the more common ones for machining of flat and cylindrical surfaces are illustrated in Fig 1 More complex machines are used to generate other shapes There are many types of grinders and grinding machines Angled grinders are suitable for manual tasks such as finishing deburring patterning cutting and polishing Belt grinders and sanders consist of a driven contact wheel and a tensioning idler wheel or pulley

[desc-10] [desc-11]

4 5 X 1 4 X 7 8 Metal Grinding Disc Type 27

https://cdn10.bigcommerce.com/s-sgvho9y4/products/86/images/1552/4.5_black_hawk_grinding_wheels__41992.1560184387.1280.1280.jpg?c=2

Grinding Machine Parts Working Operations More PDF

https://www.theengineerspost.com/wp-content/uploads/2018/04/Grinding-Machine.jpg

types of grinding - Grinding is an intricate abrasive machining process involving an abrasive wheel as a cutting tool It s renowned for its ability to produce very fine finishes and extremely accurate dimensions on metal parts Grinding involves a rotating grinding wheel made of abrasive particles which act as miniature cutting tools