casing size vs hole size The selected drilling bits sizes should provide sufficient clearance between the borehole of the drilled well and the casing to allow for drilling mud cake on the borehole and for installing casing centralizers and scratchers

Typically a well contains multiple intervals of casing successively placed within the previous casing run The following casing intervals are typically used in an oil or gas well Conductor casing Surface casing Intermediate casing optional The general rule for calculating the drill hole size is to subtract twice the wall thickness from the outside diameter of the casing For example if the outside diameter of the

casing size vs hole size

casing size vs hole size

https://www.researchgate.net/profile/Michal_Kruszewski/publication/321583677/figure/fig6/AS:569057986711557@1512685404231/Casing-and-bit-program-in-accordance-to-API-with-selection-for-the-case-study-evaluated.png

CASING AND BIT SIZE SELECTION TO MATCH THE DRILLING AND COMPLETION GOAL

https://1.bp.blogspot.com/-z_kkDxwo4e8/XfSuX_KEyRI/AAAAAAAAEAQ/IdlQ_gyGWG4nysJ93j-hVjcIVvcStM7-wCLcBGAsYHQ/s1600/Casing%2BSizes.JPG

Casing Size Selection How To Select Casing Size To Match The Drilling

https://www.drillingformulas.com/wp-content/uploads/2014/06/Table-1-Commonly-Used-Bit-Sizes-That-Will-Pass-Through-API-Casing.jpg

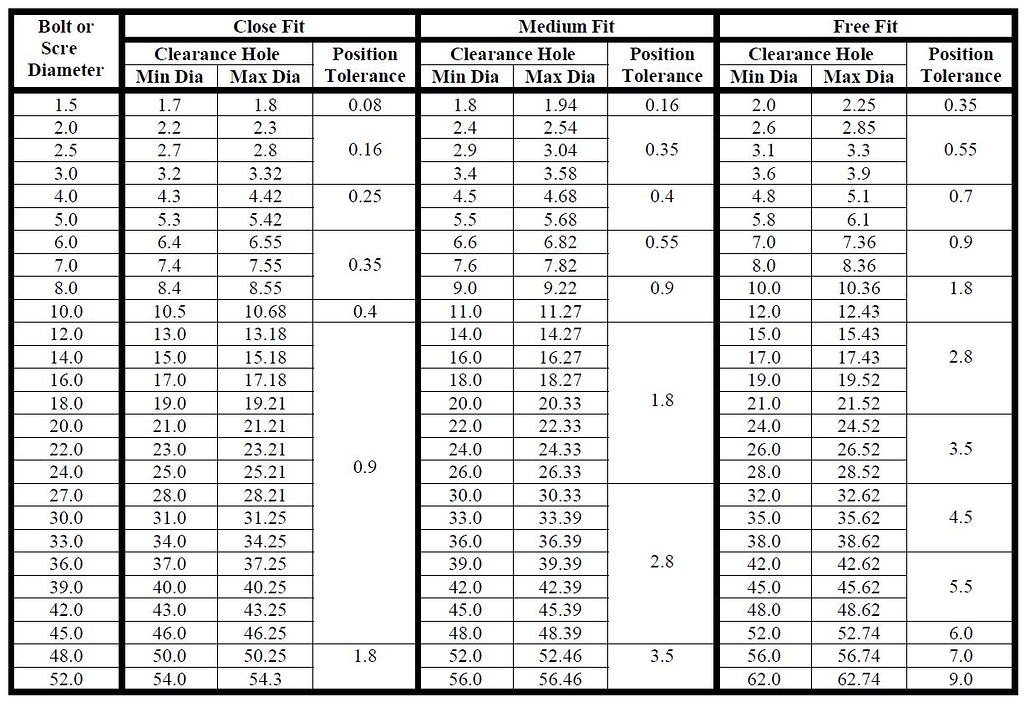

The sizes depend on a number of things Two important things to know about selection of casing size Hole size determines casing size Hole size at any point in the well except the 52 rowsCasing Dimensions and Bit Clearance Chart Components In the chart the dynamics of a well s performance in connection to the casing are tabulated On the leftmost part of the table the outer diameter OD is used to specify a

The casing sizes used in drilling onshore and offshore wells are designed from the bottom to the top starting with the production tubing In casing sizes selection you will understand Casing Weights Grades And Couplings Because of this casing sizes should be determined from the inside outward starting from the bottom of the hole The design sequence is usually as follows Proper tubing

More picture related to casing size vs hole size

Image Result For Drill Bit Size To Casing Size Chart Drill Bit Sizes

https://i.pinimg.com/originals/58/2c/db/582cdb4e77ba1c77626d60461447471b.jpg

Hole Sizes For Bolts For Printed Case Advice V1 Engineering Forum

https://us2.dh-cdn.net/uploads/db5587/optimized/3X/2/1/2115a642d6b0806ea488aac65c413359ad575092_2_1035x706.jpeg

DRILL BIT SIZES CASING SIZES YouTube

https://i.ytimg.com/vi/B76jYONARu8/maxresdefault.jpg

After artificial lift modes are determined using these methods the tubing and production casing sizes are selected and determined on the basis of the artificial lift modes Optimum usable A typical well will have a similar geometry to an inverted telescope with the hole size and casing diameter decreasing incrementally down the hole Typical hole sizes and casing diameters are 36 in 91 44 cm hole 24 in

Bit and casing size selection can mean the difference between a well that must be abandoned before completion and a well that is an economic and engineering success This chapter discusses the principles of casing design The design of a casing program involves the selection of setting depths casing sizes and grades of steel that will

File Sink Hole jpg Wikipedia

http://upload.wikimedia.org/wikipedia/commons/4/47/Sink_hole.jpg

Typical Casing Program Showing Different Casing Sizes And Their Setting

https://imgv2-2-f.scribdassets.com/img/document/352766569/original/d57760c750/1596484694?v=1

casing size vs hole size - 52 rowsCasing Dimensions and Bit Clearance Chart Components In the chart the dynamics of a well s performance in connection to the casing are tabulated On the leftmost part of the table the outer diameter OD is used to specify a