10 orb thread size SAE Thread ORB Fitting Size Versatility Widely available in various forms such as unions tees swivels and bends suitable for multiple applications Tight Seal The O ring provides an extremely tight seal capable of withstanding high pressures making it ideal for hydraulic and automotive uses

The line drawings below depict the actual sizes of the various common AN ORB thread sizes If you are unsure as to what size fitting you have lay your fitting over the appropriate drawing to determine its size For SAE O ring boss adaptors the sizing shown on our website uses the thread column to describe the fitting An easy way to think of this is that the thread would be the same thread as a JIC fitting

10 orb thread size

10 orb thread size

https://d3d71ba2asa5oz.cloudfront.net/12029072/images/radius port orb adapter fittings straight.png

O Ring Boss ORB Question Coffee Shop Red Power Magazine Community

https://s3.us-east-2.amazonaws.com/redpowerphotos/monthly_2017_10/IMG_4492.JPG.3c189fd6f0d54eead930f06a54efa733.JPG

Free Urdu Digests Kohar Mein Kiran By Seema Munaf Online Reading

https://3.bp.blogspot.com/-fm9gJvgGUe4/UPf6YGV1OvI/AAAAAAABYOk/ZSKlGHzsiPY/s1600/Kohar+Main+Kiran+by+Seema+Munaf-p5-1.JPG

ORB Size and Thread Count Each ORB size correlates with a specific number of threads per inch For example a 4 ORB fitting typically has 9 threads per inch It s crucial to match these thread counts accurately to ensure a tight leak free seal Tightening and Torque Metric Thread 10 12 14 16 18 20 22 24 26 27 30 33 36 42 48 M 10x1 0 M 12x1 5 M 14x1 5 M 16x1 5 M 18x1 5 M 20x1 5 M 22x1 5 M 24x1 5 M 26x1 5 M 27x2 0 M 30x2 0 M 33x2 0 M 36x2 0 M 42x2 0 M 48x2 0 15 16 12 THREAD CHARTS JIC SAE Metric International VISIT US AT BRENNANINC COM

SAE Straight Thread O Ring ORB This port connection is recommended by the NFPA for optimum leakage control in medium to high pressure hydraulic systems Sometimes referred to as O Ring Boss the male connector has a straight thread and an o ring The female port has a straight thread a machined surface minimal spotface and a chamfer Prepare for an in depth overview of O rings for SAE O Ring Boss ORB thread sizes 4 6 8 12 and 16 explore their significance features and discover how Summit Hydraulics provides the perfect solution for your hydraulic sealing needs

More picture related to 10 orb thread size

Hollow Hex Plug SAE ORB HP5ON Series Parker Hannifin MISUMI

https://us.misumi-ec.com/linked/vitem/mech/PIQ1/221302301138/img/HP5ON_Table.jpg

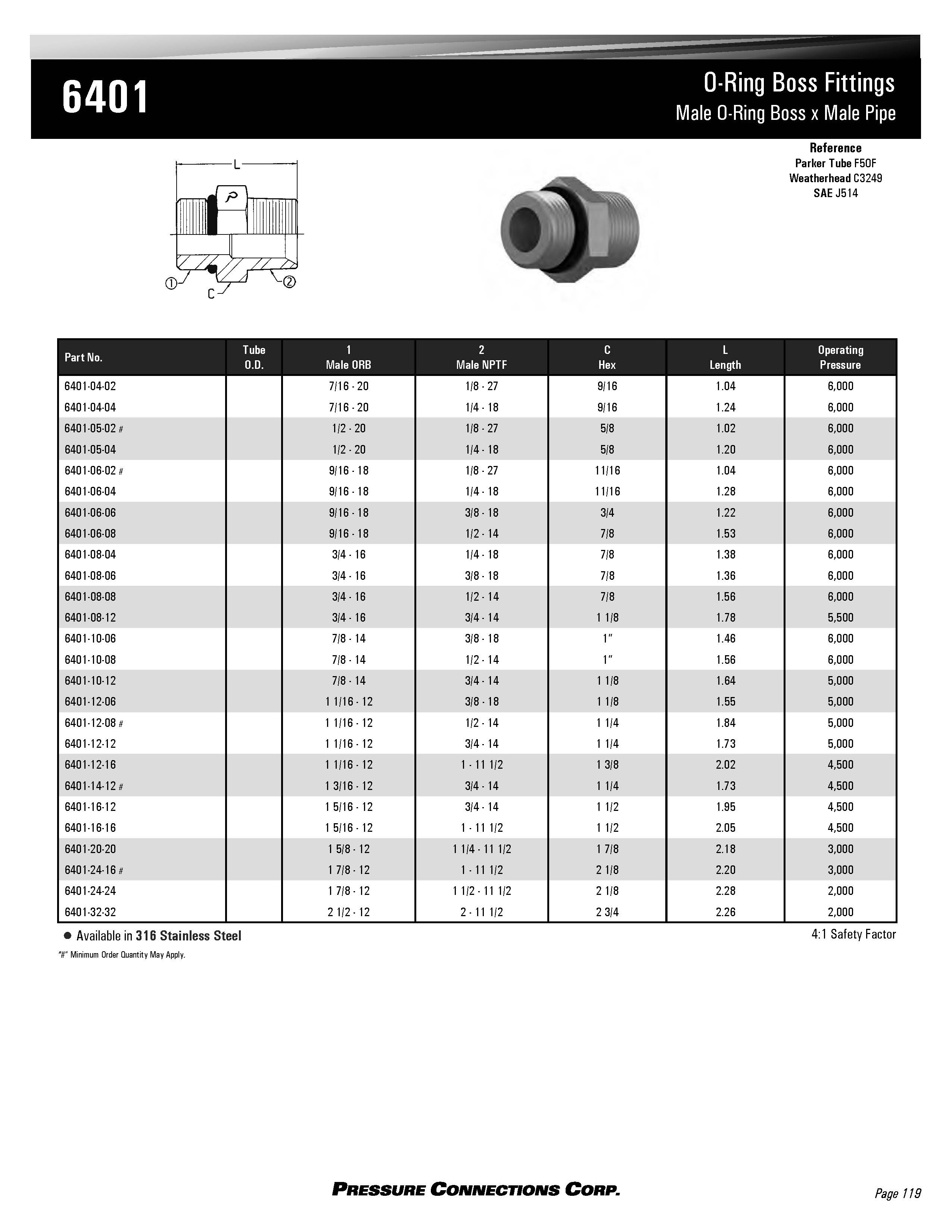

Male ORB X Male NPT Male Connector Steel 6401 04 02

https://www.universalpowerconversion.com/images/Catalog Image/Pressure/6401.jpg

ORB Fitting 45 10 ORB 10 AN Phenix Industries

https://phenixindustries.com/wp-content/uploads/2018/04/DXX45-4.jpg

O ring Boss ports ORB provide a seal by trapping the fitting s O ring inside a port cavity When a fitting is installed into the port the O ring is trapped between the fitting body hex or washer and port cavity This article will go through the steps of how to identify hydraulic coupler or adapter fitting thread sizes to help you determine the correct size thread you need for your application

Fitting Thread Size Chart The following chart is intended as a quick reference guide for thread size by dash size Click above to shop all fittings or try our search function in the top right corner Typical Layout for Expansion Joints SAE J518 Code 61 and Code 62 4 Bolt Flanges Guide on how to properly measure threads Download our O ring Boss ORB thread profiles for a printable actual O Ring Boss ORB profiles You will need to have Adobe Reader to view and print the file

3 4 16 SAE ORB X 7 8 14 SAE ORB Thread Brennan Industries 6410 08 10 O

https://images-na.ssl-images-amazon.com/images/I/819rJzfyFKL._SL1478_.jpg

7 8 14 SAE ORB X 1 2 14 NPSM Thread Brennan Industries 6901 10 08 NWO

https://images-na.ssl-images-amazon.com/images/I/71Qq0ONaA2L._SL1412_.jpg

10 orb thread size - After measuring the diameter of your threads determine their spacing in threads per inch In the case of metric connections measure the thread to thread distances To get an accurate value ensure that the thread pitch gauge is fitting well on the threads