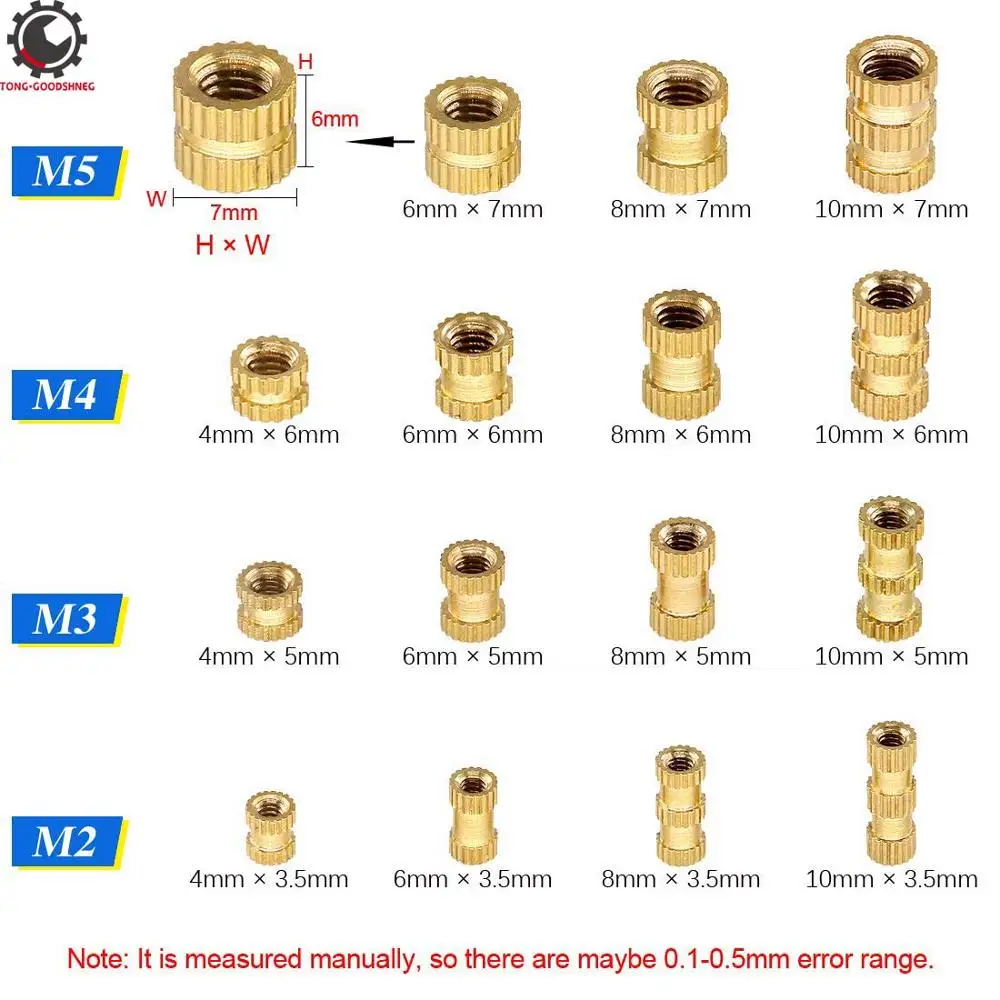

hole size for threaded inserts Installation holes are smaller than the inserts themselves they re undersized so we can t install inserts by hand force Rather we first heat the insert and then conduct that heat into

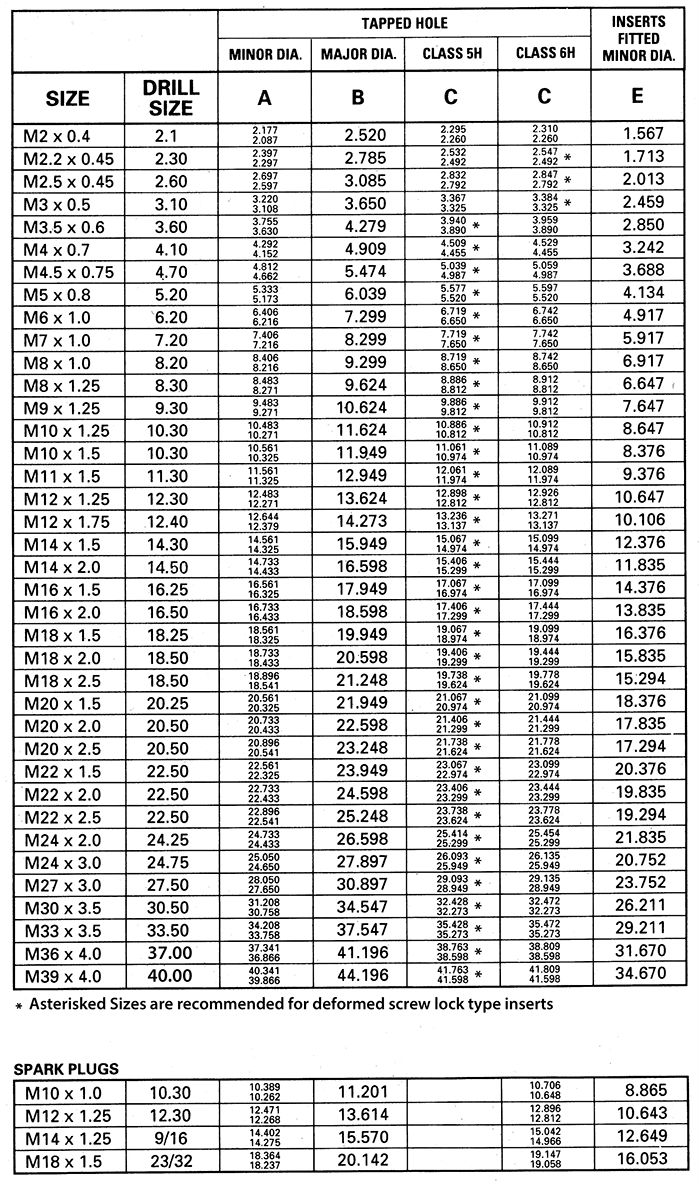

Cored or machined holes should be the correct size for the insert used If the hole is too large there is a reduction in stripping torque and pull out force For optimum performance the boss diameter should be twice that of the insert diameter Through Hole blind hole is used for designs that incorporate screw lengths shorter than the depth of the threaded insert Use the recommended hole diameter and depth through hole is required for longer screws to pass through the insert

hole size for threaded inserts

hole size for threaded inserts

https://ae01.alicdn.com/kf/HTB1u54Ua1L2gK0jSZFmq6A7iXXad/M2-M3-M4-M5-Female-Thread-Knurled-Brass-Threaded-Insert-Embedment-Nut-for-3D-Printing-Threaded.jpg

Threaded Inserts For Plastic Wood Injection Rotomolding Cross Tools Co

https://crosstools.com.au/images/moulders inserts 010.jpg?crc=4099967255

Tebru 10pcs 308 Type 3 hole Carbon Steel Self tapping Screw Thread

https://i5.walmartimages.com/asr/0d662272-4e30-45ff-b772-695f38df766a_1.c6aa766b049b552380890b6cb78e6924.jpeg?odnWidth=612&odnHeight=612&odnBg=ffffff

Optimum Design Guidelines Holes for Inserts installed by heat or ultrasonics should always be deeper than the length of the Insert The assembly screw should never bottom out in the hole as jack out would result The recommended minimum The hole should be the correct size to accommodate the body of the insert and should be as straight as possible Tapping the hole If the threaded insert has external threads the hole should be tapped with the appropriate tap to match the insert s threads

Using the Hole tool or similar depending upon your CAD program create a counterbored hole on the specified points with the recommended hole depth and major diameter A of the taper for the insert Base on the m3 is about 4 3 so 4 5 is a good size depending on how small your holes actually print That little step on the bottom is so you can set the insert in place without it tipping over So once you print and see how big your

More picture related to hole size for threaded inserts

How To Insert Threaded Inserts

http://www.modelenginenews.org/techniques/images/ti_02.jpg

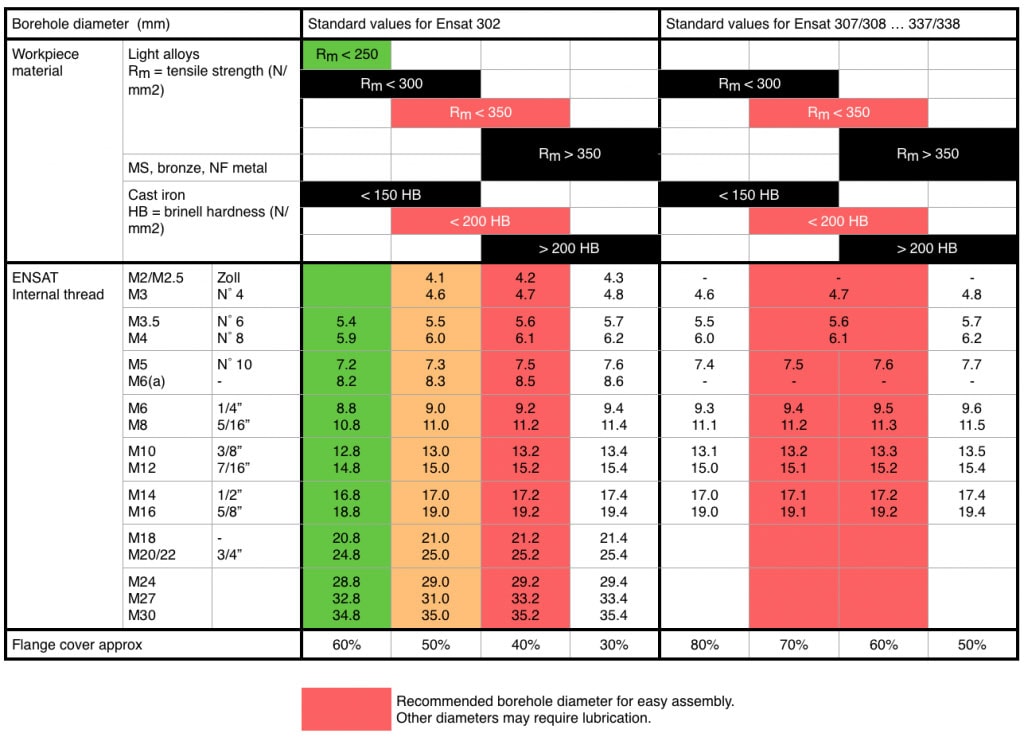

Ensat Tappex Threaded Inserts

https://www.tappex.co.uk/wp-content/uploads/2017/03/ensat-performance-data.jpg

Threaded Inserts For Plastic Wood Injection Rotomolding Cross Tools Co

https://www.crosstools.com.au/images/moulders inserts 011.jpg?crc=294837297

Hole configuration hole diameter and hole depth can have a significant impact on threaded insert performance and installation Recommended hole configuration and dimensions are included with the insert specifications which follow Threaded Inserts for Wood 800 234 5613 ezlok Created Date 1 29 2020 10 23 01 AM

[desc-10] [desc-11]

Helicoil Type Inserts Metric Tapped Hole Size Table Cross Tools Co

http://crosstools.com.au/images/helicoil metric tapped hole chart 24-12-2014.jpg?crc=361914958

Threading Key Inserts

https://www.protolabs.com/media/1012888/threaded-holes-technical-illos-key-inserts-570x308.jpg

hole size for threaded inserts - The hole should be the correct size to accommodate the body of the insert and should be as straight as possible Tapping the hole If the threaded insert has external threads the hole should be tapped with the appropriate tap to match the insert s threads