3 4 bolt capacity Design aid Table of design properties for individual metric hexagonal bolts including stress area yield strength ultimate strength shear resistance tensile resistance interaction between shear and tension bearing resistance punching shear resistance According to EN 1993 1 8 2005 Section 3 8 Supported National Annexes

Tensile strength and proof loads SAE bolts Proof Load is the maximum tensile force that can be applied to a bolt that will not result in plastic deformation Clamp load equals to 75 of proof load Bolt capacity is based on the smaller of bolt shear and material bearing capacities and if desired is adjusted based on bolt spacing i e reductions in capacity are possible when bolt spacing is less than optimal

3 4 bolt capacity

3 4 bolt capacity

https://www.duplexfastener.com/img/hsfg-bolts-fasteners-dimensions.gif

Bolt Vs LCT EBB Rocko Airsoft

https://m.blog.hu/ro/rockoairsoft/image/bolt_vs_lct_ebb/bolt.jpg

Metric Eye Bolt Sizes Locedside

https://i.accu.co.uk/360/_APC/SLE-A2/0_14.png

Sizes from 5 16 up torque in foot pounds Size and pitch Nominal diameter Stress Area in2 Grade Proof load ksi 824 1274 1799 723 1117 1577 3460 824 1274 1799 3955 31 Combined Thread and Body Bolt Elongation Under Preload Formula and Calculator With torque or turn on a bolt thread we re trying to control the tightening process through the forces applied to or the motion of the nut

Below are the chemical and mechanical requirements per the ASTM A325 specification In addition you will find the estimated mechanical property requirements for each diameter of bolt required One thing to note is that with the implementation of ASTM F3125 Grade A325 the mechanical properties differ slightly as indicated below The following tables gives the shear strengths in N mm 2 of stainless steel bolts and shear capacities in kN for bolts of diameter M10 to M24

More picture related to 3 4 bolt capacity

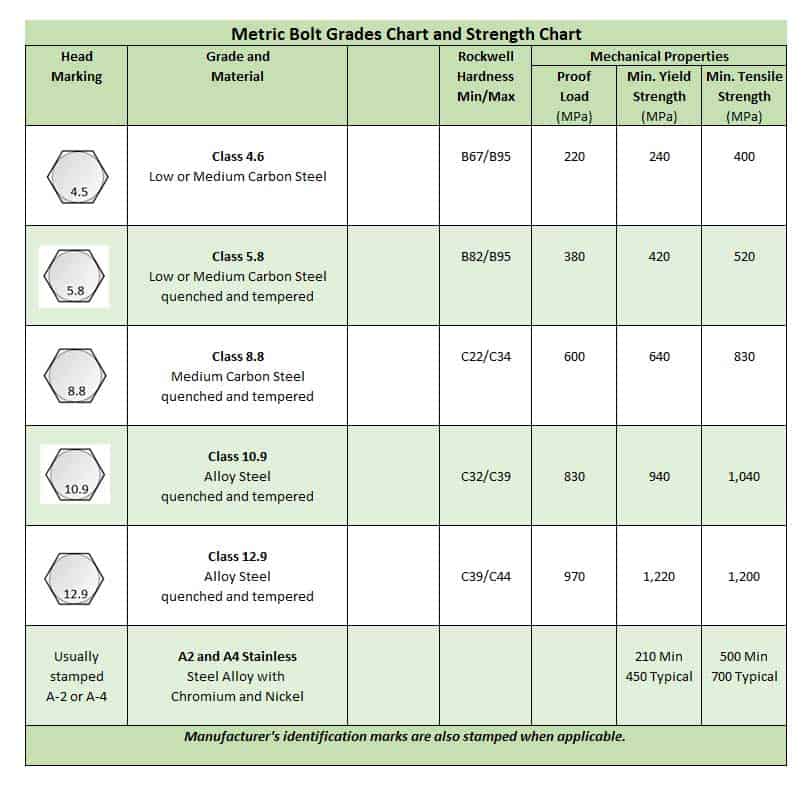

Bolt Grade Chart

https://www.cnccookbook.com/wp-content/uploads/2022/09/MetricBoltMarkings.jpg

How To Select Bolt And Screw Sizes

https://www.hydrafitnessexchange.com/uploads/blogpost/7843d730ddd2bdfeb5f7fed64ad39771.png

5 Lug Bolt Pattern Template Johnson Trailer Parts

https://i0.wp.com/johnsontrailerparts.com/wp-content/uploads/2018/05/5-Lug-Bolt-Pattern-Template-Bolt-Circle-Template-Back-1.jpg?fit=2000%2C2000&ssl=1

The three main force groups which can be found to act on connections are Shear and Bearing Friction and Axial Tension The below table has been provided as a rough guide to the capacities of individual shear and axial tension that bolts can withstand ASTM F3125 F3125M is a structural bolt specification covering inch and metric bolt grades This specification contains 4 inch series bolting grades A325 F1852 A490 and F2280

Comparison of Shear Strengths of Grade 2 5 and 8 Screws The industry standard for determining shear strengths of fasteners is to take 60 of the minimum Ultimate Tensile Strength of the fastener for single shear joints and 120 for double shear joints AFT Fasteners provides a helpful resource on carriage bolts including carriage bolts sizes charts specifications on galvanized carriage bolts grads 5 8 carriage bolts and stainless steel plus material hardness strength and thread length

Bolt Chart

https://cdn.slidesharecdn.com/ss_thumbnails/boltchartupdatednew2016-161102183949-thumbnail-4.jpg?cb=1478112015

Bolt SAPO Mag

https://mb.web.sapo.io/a28325b00b51beb139d2d0400506bfaceb92f45d.jpg

3 4 bolt capacity - The allowable bearing load at a bolt hole is 1 5Fudt where Fu is the specified tensile strength d is the nominal bolt diameter and t thickness of connected part Table 7 25 tabulates maximum sizes for standard oversize and slotted bolt holes