3 1 2 tubing capacity This document provides specification data for 3 1 2 inch tubing including the outer diameter wall thickness grade tensile strength collapse rating internal yield pressure estimated fluid capacity and displacement per foot recommended torque values for connections and a disclaimer that the information is for reference only and field

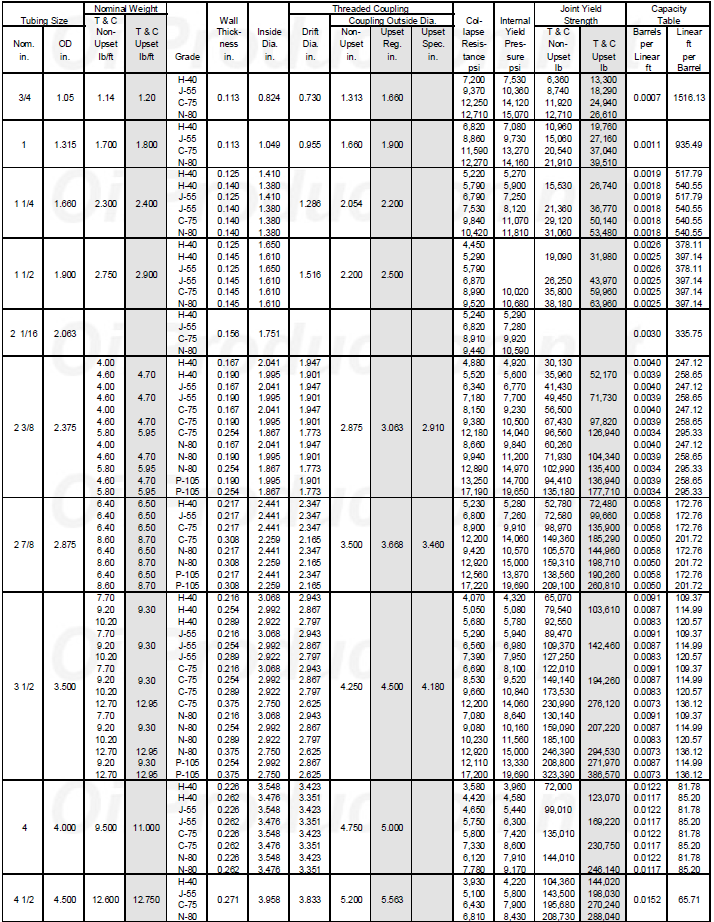

Capacity Displacement Adjusted Weight are best estimates from the OEM and are based on pipe purchased at 95 RBW with longer than standard tool joints Nominal thickness of IPC is 009 when applied Tubing Capacities Body Yield Strength 285 000 lbs 1268 kN API Collapse 13 530 psi 933 bar Internal Yield 13 970 psi 963 bar Joint strength 174 000 lbs

3 1 2 tubing capacity

3 1 2 tubing capacity

https://images.squarespace-cdn.com/content/v1/58702160e6f2e1c46d36e7df/1484253793245-L3PHQWXM3WANKTT377YZ/02-tubing-sizes.png

Tubing Specifications Production Technology

http://production-technology.org/wp-content/uploads/2017/10/Tubing-specifications.png

Ss Pipe Schedule Chart Images And Photos Finder

https://eagletube.com/wp-content/uploads/2017/12/2018capture-pipe.png

Opogc Tubing Size Nominal Weight Grade Wall Thick N n ess in Inside Dia in Threaded Coupling Col lapse Resis tance psi Internal Yield Pres B sure Joint Yield Strength Capacity Table T C Non Upset lb ft Weight displacement and capacity are approximate and can vary by 10 or more depending on OD specified wall wall tolerance and internal coating options It is the responsibility of the customer and the end user to determine the appropriate performance ratings acceptable use of the product maintain safe operational practices and to

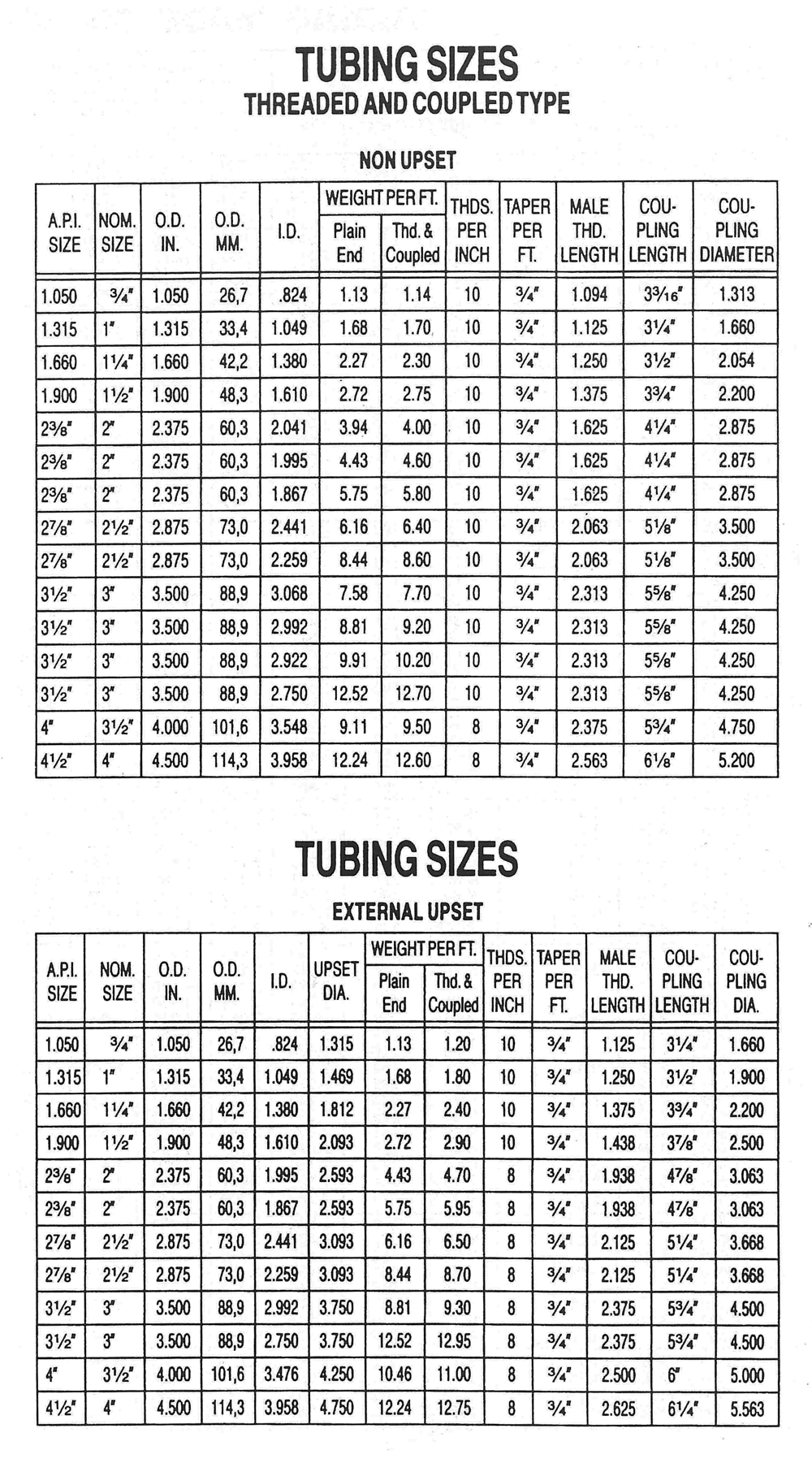

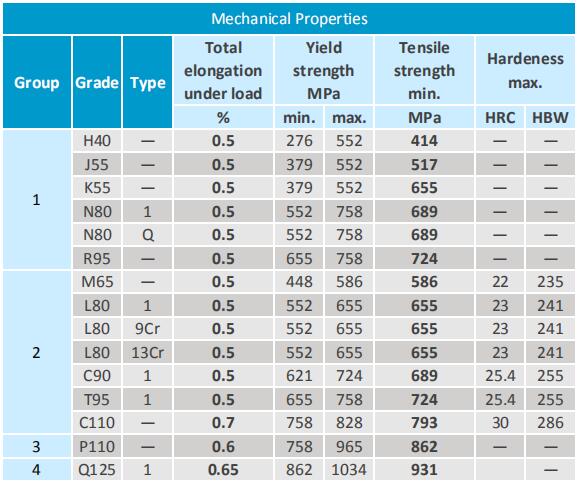

3 1 2 L80 12 95 LBS FT PH6 TUBING The technical information contained herein including the product performance sheet and other attached documents has been extracted from information available from the manufacturer and is for reference only and not a recommendation Tubing Pipe Dimensions and Weight Chart for API non upset external upset and intergral tubing connections Lables Outside dia Nominal linear masses Wall thickness Inside dia 3 1 2 12 70 12 95 3 500 12 70 12 95 0 375 2 750 12 53 4 00 8 20 4 40 3

More picture related to 3 1 2 tubing capacity

API 5CT P110 Casing And Tubing Pipe Specification Octal

https://www.octalsteel.com/wp-content/uploads/2019/01/api-5ct-octg-tubing-mechanical-properties.jpg

3 4 X 049 316 Stainless Steel Seamless Tubing Alabama Industrial

https://cdn.shopify.com/s/files/1/1313/5337/products/Stainless_Steel_Tubing_10ccca7b-f88a-4e5f-8040-d80104b1d86f_530x@2x.jpg?v=1568841773

12 Long Piece Of Stainless Steel Tubing 1 2 OD 0 020 0 035 Wall T

https://cdn.shopify.com/s/files/1/2400/0975/files/12-stainless-steel-tubing-1-2-OD-0-020-0-035-wall-thickness_2048x.jpg

3 1 2 P 110 12 95 LBS FT TS HD TUBING The technical information contained herein including the product performance sheet and other attached documents has been extracted from information available from the manufacturer and is for reference only and not a recommendation Manually calculating coiled tubing specifications can be challenging so we ve been working on a solution We ve developed an online calculator that provides accurate specifications simply by choosing your tubing grade and selecting OD wall thickness and length via a turning dial

Tubing is basically a seamless pipe sold at irregular lengths ranging from 28 to 40 ft A tubing string is put together by selecting and putting together an appropriate mix of lengths of tubing joints Joints are available from 2 to 12 ft long with a 2 ft step increment for each size Tubing Mechanical Properties and Specifications Loading Download the Workstrings International Pipe Specification Mobile App on the App Store or Google Play Rust Grip is the leading external coating solution for minimizing pipe corrosion in

Round Tubing

https://nebula.wsimg.com/4ed468029be9fcda029e4b34ea517067?AccessKeyId=D08587C4705234243516&disposition=0&alloworigin=1

Stainless Steel Tubing Cutter The Electric Brewery

https://cdn.shopify.com/s/files/1/2400/0975/files/Stainless-steel-tubing-cutter_2048x.jpg

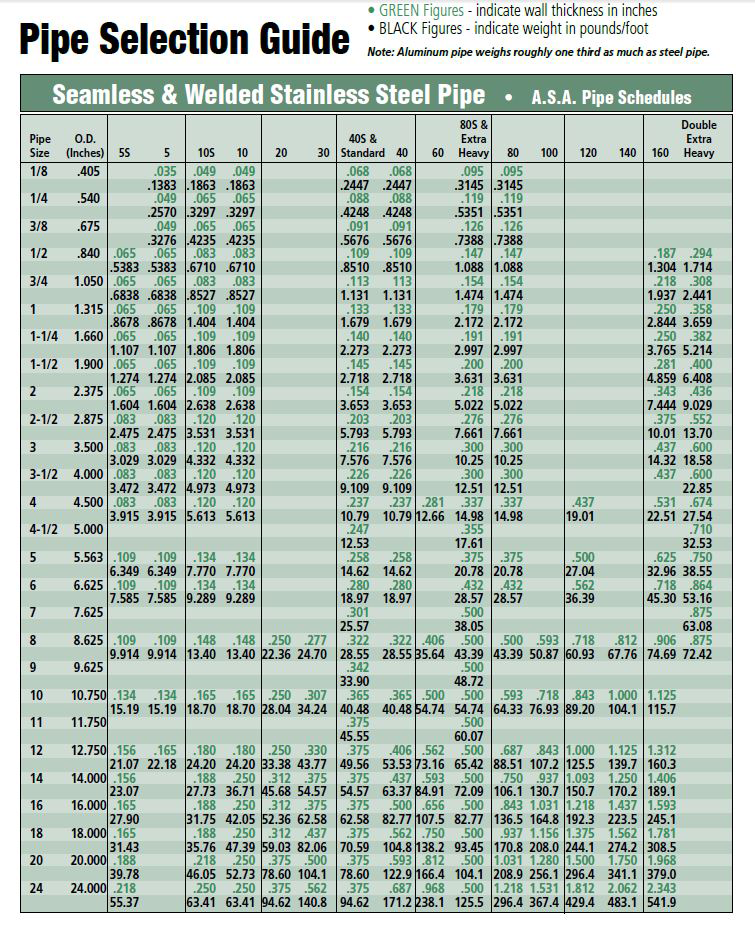

3 1 2 tubing capacity - Flow Capacity Pipe and Tubes ANSI schedule 40 pipe The following chart contains the maximum recommended flow rates at the given pressure for ANSI schedule 40 pipe This chart is applicable for designing compressed air systems