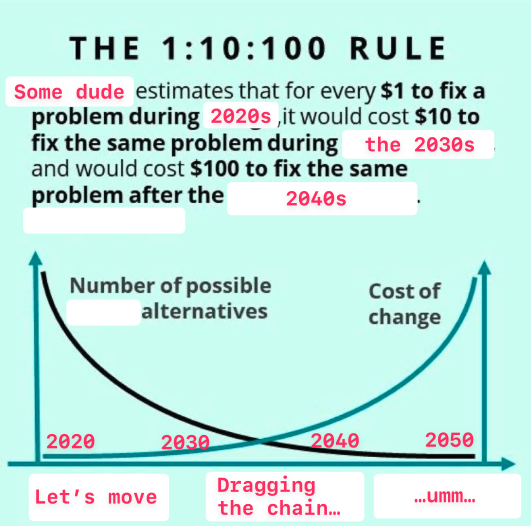

1 10 100 rule What s the 1 10 100 rule Applied to manufacturing s supply chain the 1 10 100 rule states that cost increases by a factor of 10 if a quality issue is undetected in each stage of the chain That is if it costs 1 to detect and solve a product defect pre production it will cost 10 to do so during production and if the problem is still

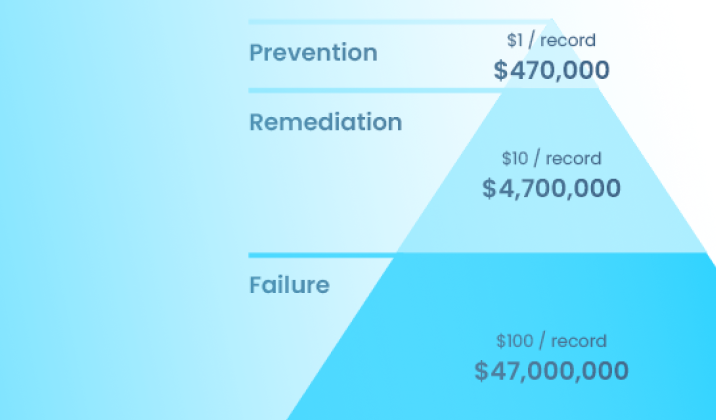

According to the 1 10 100 rule when you rectify your data after getting feedback you lose 10 for every 1 due to your reactive approach to data quality 100 for doing nothing You The 1 10 100 Rule is related to what s called the cost of quality Essentially the Rule states that prevention is less costly than correction is less costly than failure It makes more sense to invest 1 in prevention than to spend 10 on the correction That in turn makes more sense than to incur the cost of a 100 failure

1 10 100 rule

1 10 100 rule

https://utilityequipmentparts.com/wp-content/uploads/2022/06/1-10-100-scaled.jpg

The 1 10 100 Rule Accuvance

https://accuvance.com.au/wp-content/uploads/2022/09/Accuvance-110100-rule.png

Three Common Misconceptions That Are Costing You Money

https://www.hallam-ics.com/hs-fs/hubfs/pic.jpg?t=1542047069750&width=1024&name=pic.jpg

Introducing the 1 10 100 rule This rule states that detecting quality problems early in the manufacturing process is less costly than catching a quality challenge later in the manufacturing process The 1 10 100 rule of data quality by George Labovitz and Yu Sang Chang serves as a poignant reminder of the escalating costs tied to data quality Let s dive into the depths of this rule understand its implications and explore how Truugo s specialized services align with its principles

The 1 10 100 rule is a framework that quantifies the costs associated with data quality at different stages It suggests that it is far more cost effective to prevent data issues upfront than to correct them later or suffer the consequences of failure Let s explore each cost category in detail What is the 1 10 100 Rule in Software Development Quality Control The 1 10 100 rule simply refers to the cost to fix defects aka bugs by phase step in a software development lifecycle Preventing a bug by catching it while writing code costs little to nothing thus the 1 to fix

More picture related to 1 10 100 rule

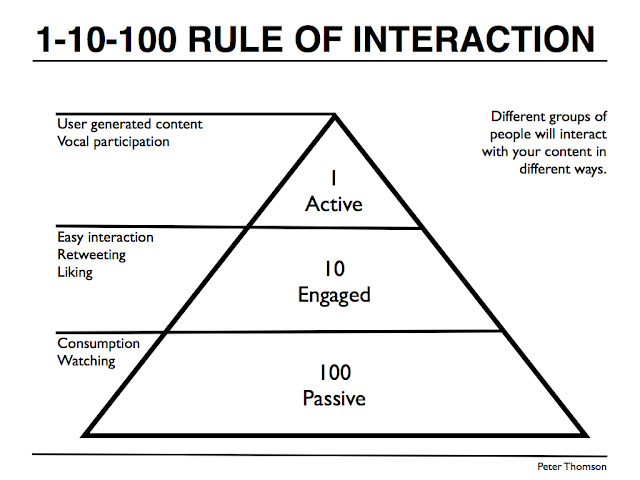

1 10 100 Rule Peter J Thomson

https://www.peterjthomson.com/wp-content/uploads/2012/09/Strategy-Diagrams.026.jpg

1 10 100 Rule In Quality Software Development AKF Partners

https://akfpartners.com/uploads/blog/1-10-100_Rule.png

What Is 1 10 100 Rule How Organisations Will Get Benefit And Save

https://media-exp1.licdn.com/dms/image/C5612AQFfxcF5P1gkBg/article-cover_image-shrink_720_1280/0/1594574720348?e=2147483647&v=beta&t=Pz2mTG5Bgip5HL0bltpvQf4cDiKOM73X3xnYbxzzZQ8

Gary Allemann 1 10 100 best practice approach costs The 1 10 100 rule Discover the groundbreaking 1 10 100 rule a quality management concept by G Loabovitz and Y Chang Learn how it quantifies hidden costs tied to subpar quality and why it In phase one of the 1 10 100 rule 1 equates to the amount it costs to verify data in the first instance This is the cheapest and most effective way of ensuring you capture clean and accurate data In phase two the amount increases to 10 a significant rise compared to the 1 in phase one

The 1 10 100 Rule is related to what s called the cost of quality Essentially the rule states that prevention is less costly than correction is less costly than failure It makes more sense The 1 10 100 rule proves that sooner is better Data quality is not a problem that can be tackled once and forgotten and tackling it soon and often is better than late or not at all Continual improvement and maintenance is the key to keeping waste to a minimum in business

What Is The 1 10 100 Rule Of Data Quality Aunalytics

https://www.aunalytics.com/wp-content/uploads/2021/12/What-is-the-1-10-100-rule-of-data-quality_-.png

The 1 10 100 Rule Impact Labs Australia

https://impactlabs.com.au/wp-content/uploads/2022/08/1-10-100-B3.png

1 10 100 rule - Introducing the 1 10 100 rule This rule states that detecting quality problems early in the manufacturing process is less costly than catching a quality challenge later in the manufacturing process